Powerhorse HorizontalVertical Electric Log Splitter 8-Ton 15 Amp 120V Motor. Visual image monitoring with its easy access to sampling information and high robustness has become the most promising method.

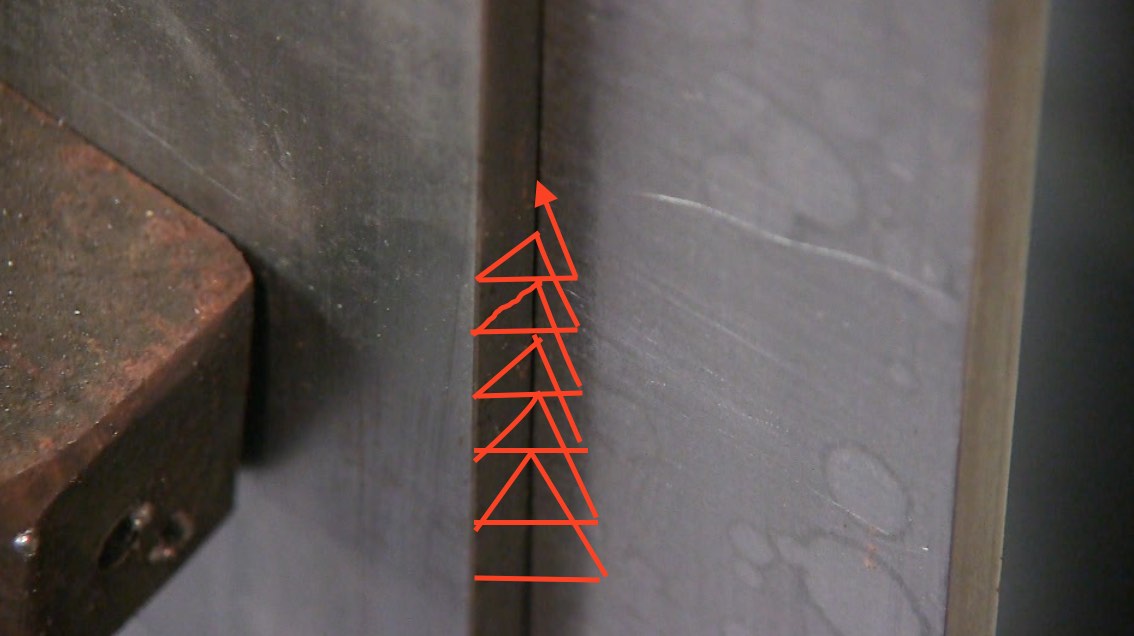

This Vertical Mig Welding Technique Will Penetrate

MIG Welding Wire for TIG Welding.

. 2017 presented the analysis of welding current to quantify the pattern of the current using Short Time Energy signal processing and to determine the stability of the welding process. TIG welding works well in all positions on almost any metal. 10 Sep2019 - Woodworking routers are a commonly found tool used to make cuts create edging joinery and hollow out wood.

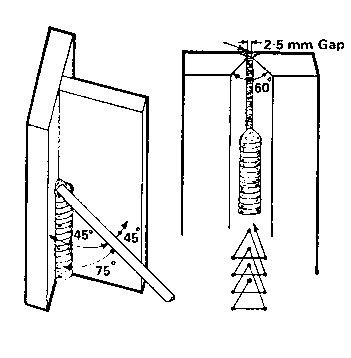

You want the heat to be on the hot side and once you do it for a while it is as easy as flat. Welding parameters tool geometry and joint design exert significant effect on the material flow pattern and temperature distribution thereby influencing the microstructural evolution of material. Overhead MIG Welding Techniques.

The only differences between a flat horizontal vertical and an overhead weld is how you mentally approach the task. To create fuller penetration welding with the 6010 rod the welder should whip the electrode with 332 12 inch distance and immediately pull in back around 18 inch and then pause for split of a second to allow the rod to establish the weld puddle on the spot and whip forward and pull backward with the same movement pattern. They can also be used to execute flawless pattern work or joining work like dadoes and rabbets.

Welding horizontally vertically or even upside down is achievable on a variety of thicknesses but ¼ is really what this welder is setup to weld perfectly on. Figure 3 Coining bottom bending and air forming affect stressstrain properties differently. As with all MIG welders the push-style welding produces the best welds for this welder as it creates a hotter weld than the pull-style it is a 110 volt welder after all.

They can also be used to execute flawless pattern work or joining work like dadoes and rabbets. Overhead MIG welding requires the MIG gun tilted 5 to 35 degrees toward the direction of the weld. Most of it comes down to a positive.

Bankers skilled welders can Mig Tig Flow or Spot weld aluminum carbon steel and stainless steel alloys for use in a variety of industrial and architectural applications. Welding is a fabrication process that joins materials usually metals or thermoplastics by using high heat to melt the parts together and allowing them to cool causing fusionWelding is distinct from lower temperature techniques such as brazing and soldering which do not melt the base metal parent metal. Just like any other welding process there is not a single pattern or way to make a good weld.

The curved line in the air forming zone shows how springback changes at different bend angles. In bottoming and coining bending methods that usually produce 90-degree bend angles the line curves to the right of the vertical axis showing how the metal springs forward. Lincoln Electric Auto-Darkening Variable Shade Welding Helmet with Grind Mode Fierce Red Graphic Pattern Model K3063-1 Only 119.

With the ability to achieve these finishes and more its no surprise these tools are a household name for woodworkers. Inspiring Growth and Success with quotes and life advice to help you succeed grow and achieve your goals. Welding the wire mesh to a frame for architectural use or creating flow welded edges for industrial heat treating baskets is commonplace with our products.

In this section a few major factors affecting FSWFSP process such as tool geometry welding parameters joint design are addressed. In addition to melting the base metal a filler material is typically added. With the ability to achieve these finishes and more its no surprise these tools are a household name for woodworkers.

MIG welding vertical up technique require the nozzle point upward 35 to 45 degrees. Mazlan et al. 10 Sep2019 - Woodworking routers are a commonly found tool used to make cuts create edging joinery and hollow out wood.

Solid Wire Vertical Up Miller Welding Discussion Forums

Best Mig Welding Techniques For Everyone

Welding Vertically Mig Welding Forum

Smaw Weave Patterns Google Zoeken Welding Art Welding Projects Welding

0 comments

Post a Comment